CNC Milling and Job Work

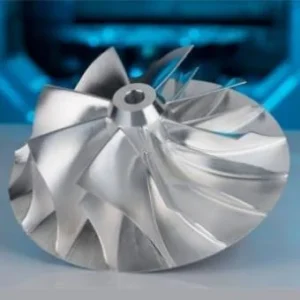

Mahanadhi Industrial, Manufacturers and suppliers of 3 axis, 4 axis and 5 axis CNC Milling parts and Components from India to various companies in Automotive, Chemical and General Engineering Segments. at best milling cost per hour.

We pride ourselves on using the most advanced CNC and traditional milling machinery for manufacturing high-quality precision milled components. Upholding maximum precision tolerance, our cutting-edge equipment allows for variable spindle speeds, coolant systems and power-operated table speed capabilities. We also offer several varieties of machining solutions that are able to process an extensive range of materials, such as high-speed aluminum and plastic machining, as well as fiberglass and other composite substances.

We work with a wide variety of milling machinery including vertical milling, planer milling, and knee-type milling. Offering top-notch CNC and traditional vertical milling operations on all short-run production volumes, we invite you to contact our company for further information.

Vertical Milling Center Features

4-axis capability Upto 1 meter bed size with High-speed 10,000 rpm gearbox 32-station tool changer – more tool slots means less time stopping production to change out tools on complex parts, saving time on production runs and offering competitive pricing.

Three-vice fixturing – with three vices integrated into the machine, we can mill three smaller parts simultaneously, or one extra-large large part. We can also flip or rotate the part if needed. This means greater flexibility for more complex parts.

Milling Processes:

- Boring

- Drilling

- Counter-blocking and sinking

- Profiling

- Tapping

- Popular Vertical Milling Applications

- Hydraulic manifolds

Materials:

- Titanium

- Polypropylene

- Stainless Steel (SS303, SS304, SS316 & Duplex)

- Inconel

- Spring Steel

- Other carbon Steel